Technique What you can do with Kisogawa Senjyu Co., Ltd.

Processing

-

Processing 01

BOTADEGI processing

Hybrid processing that combines the gentle colors of plant dyes with digital colors. The colors become brighter over time, so you can enjoy the changes every time you wash it.

-

Processing 02

Botanix processing

This features a natural and deep color dyed with 100% plant dyes. By incorporating the natural power of plants, you can feel calmness.

-

Processing 03

Five types of

hygienic processingWith antibacterial processing that suits your purpose, you can add value to safe and secure fabrics.

-

antibacterial deodorant processing

This has an antibacterial and deodorant effect due to the power of silver ions. It also has excellent wettability and moisture retention. moisturizing properties due to amino acids.

-

deodorant processing

Zinc oxide decomposes components that cause odor and exerts a deodorizing function.

In addition, the water-absorbing and quick-drying treatment make it refreshing and comfortable to wear. -

moisture-retaining processing

This is an antibacterial agent derived from the natural components of grapefruit seeds. It provides excellent wettability and moisture retention, and also has a deodorant effect.

-

antifouling processing

In addition to preventing stains, it also imparts water absorption to polyester and nylon fibers, for a clean finish with a smooth texture.

-

cool touch processing

Xylitol processing provides a cool and soft touch, with energy that absorbs sweat and moisture. In addition, the power of silver ions provides an antibacterial and deodorant effect.

-

Company Promise

Responsiveness

Responsiveness based on

the customer’s perspective

Equipped with a processing machine that meets your needs, from small lots to large lots, and from single to composite materials, we pursue delicate textures and new textures required by the times and are committed to manufacturing “from the customer’s perspective.”

Quality assurance Providing safe and secure processed products

Color management

We use the CCM (Computer Color Matching) system to create colors that meet the needs of our customers, providing delicate colors for any type of material. Stable color assessment is performed in the light source box required for color matching. We use a colorimeter to manage the digitization of metamerism.

| Light source | Various general fluorescent lamps |

|---|---|

| D65 | White fluorescent lamp |

| TL84 | Neutral white fluorescent lamp |

| F | Daylight fluorescent lamp |

| UV | Black light |

Robustness management

We check the general dyeing fastness with house data based on the JIS standard. “Unlikely to change in color,” “unlikely to fade,” etc.

Physical property management

We conduct tests related to the consumption performance of the fabric (finished product).

“Shrinkage in laundry,” “pilling (hairball),” etc.

Quality management

We aim to make safe and secure products by using dyes, chemicals, processing agents, etc. that are in compliance with chemical substance regulations. The final inspection of our fabrics is based on a check of the quality, texture, color, standard width, standard length, and defects (scratches, stains, etc.), as well as the use of a needle detector (metal pieces, etc.).

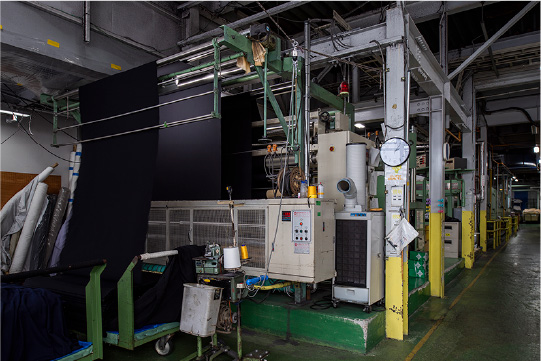

Process & Facility

01

Preparation process

01 Color matching

-

CCM (Computer Color Matching)

Measure the color sample and calculate the dye formulation.

Measure the color difference between the original color and the dyed finish.

-

Automatic liquid dispenser

Weighing device for the dyeing tester. Dyes can be measured at high speed and with high accuracy. Prevents weighing mistakes and artificiality resulting from human error and produces stable colors.

-

Multicolor rotary pot dyeing tester

Up to 24 pots can be dyed at the same time. Each pot can be dyed under different conditions.

0204

Dyeing processing

02 Dyeing

-

Constant pressure liquid flow dyeing machine

- Number of units owned

- 5

- Weight of the machine

- 100k - 150k

-

High pressure liquid flow dyeing machine

- Number of units owned

- 12

- Weight of the machine

- 60k - 200k

-

Constant pressure liquid flow dyeing machine

(testing machine)- Number of units owned

- 1

- Weight of the machine

- 5k - 20k

-

High-pressure liquid dyeing machine

(testing machine)- Number of units owned

- 4

- Weight of the machine

- 5k - 25k

03 Dehydration

-

Centrifugal dehydrator

- Number of units owned

- 2

- Weight of the machine

- -

04 Opening the fabric

-

Opening machine

- Number of units owned

- 2

- Weight of the machine

- -

0507

Finishing process

05 Drying

-

Tumbler dryers

Can dry fabrics without tension

- Number of units owned

- 4

-

Pin dryer

Resin processing can be performed consecutively to padding

- Number of units owned

- 1

- Working width

- 120cm - 180cm

06 Nap-raising

-

Nap-raising machines

- Number of units owned

- 3

- Supports an effective width

- 200cm

-

Shirring machines

- Number of units owned

- 2

- Supports an effective width

- 200cm

-

Polisher machine

- Number of units owned

- 1

- Supports an effective width

- 200cm

07 Finishing

-

Continuous steaming machine

- Number of units owned

- 1

- Supports an effective width

- 180cm

-

Heat set machine

Supports edge cutting and center cutting

- Number of units owned

- 1

- Supports an effective width

- 90cm - 250cm

08

Inspection process

08 Inspection

-

Cloth inspection machine

- Number of units owned

- 5

-

Automated packaging machine

- Number of units owned

- 1